Why Do We Keep Buying Tein Coilovers?

- Roger Maeda

- Dec 31, 2018

- 12 min read

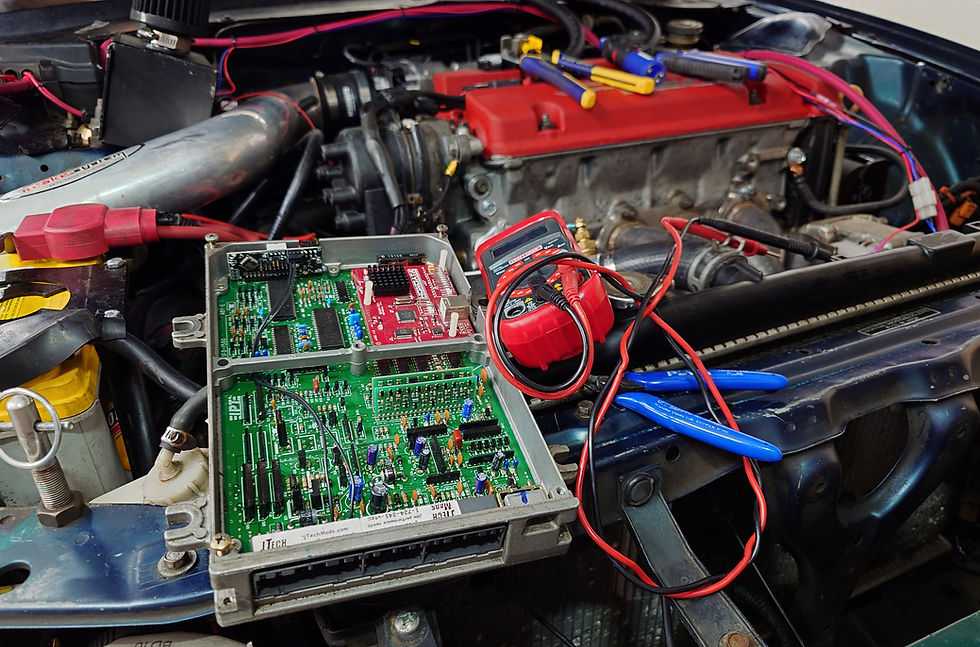

Earlier this week, we unbolted the battle-worn coilovers from the StudioVRM Prelude and shipped them off to Tein USA in Downey, California. This will be their third trip to the west coast service center, having already gone through one rebuild and two revalving services over the last 10 years.

Given how many solid options there are in the "under $500 (USD) per corner" category of coilover suspension kits nowadays, it might come as a bit of a surprise that we aren't just buying a set of new coilovers from a different company. If nothing else this is a big surprise for me. In an effort to shave off more precious seconds from our lap time, I have been actively talking to a number of different suspension companies about getting a set of custom racing dampers built for the Prelude. But when we sat down at the end of the season and compared each company's offerings, it was Tein that came out as the best option.

Given this unexpected turn of events, I thought I'd spend a few minutes and talk about the benefits and drawbacks of using Tein suspension dampers, and why StudioVRM will continue to run on their ubiquitous green shocks throughout the 2019 season.

Are you saying Tein makes the BEST suspension dampers?

Not quite. As far as I'm concerned, no one makes a set of suspension dampers that are the "best" at everything.

One of the cold hard truths of hydro-pneumatic suspension dampers is that they are one-trick ponies. They can all do one thing really well, and tend to suck at everything else.

This is why OEM manufacturers still use sealed twin-tube shock cartridges on new cars. There's no other way to provide the ride comfort and durability that most customers expect, even on sporty coupes like the popular Subaru BRZ / Scion FRS / Toyota 86 triplets. On the same token, this is also why the high-budget Porsche guys don't drive to the supermarket on their JRZ competition dampers. The ride would be bone-shattering and the expensive aluminum shocks would start falling apart within a few thousand miles.

I am saying that Tein's coilover kits do a very good job of meeting the needs of budget-conscious club racers and track day enthusiasts. Specifically, we need dampers that are:

Fade resistant enough to stay consistent through a 1-hour+ race session on a road course

Durable enough to withstand the occasional high-speed off-track excursion

Have the ability to customize the valving for our car and specific needs

Have a bolt-in application for our car

Come in at a cost of under $500 per damper (not including springs and top hats)

The differences between one damper manufacturer and another lie in how they go about meeting these needs. Let me talk you through some of the "hows" that make Tein's products so unique and attractive to budget-minded racers like us.

Unusually Tough and Fade-Resistant Construction

If there's one thing that all club racers need out of their suspension dampers, it's consistency. They need their cars to handle the same way, regardless of whether they are on lap 5 or lap 50. Tein solves this problem in an unusual way: They use the largest diameter damper body possible, both to increase the surface area of the damper and to fit in as much shock oil as they can.

These twin tube Tein dampers might not cost very much, but they offer excellent fade resistance lap after lap. They are also robust enough to handle pretty much anything you'll run into - or drive over - at the track.

This is the complete opposite of the approach taken by most other aftermarket suspension companies. Larger diameter damper bodies mean more material and more weight, which in theory would be completely out of place in the extremely weight-conscious world of road racing. It turns out that in practice, this approach works remarkably well.

A few years ago I had the opportunity to compare Tein Basics against a set of Koni Yellows on a B14 chassis Nissan Sentra at a local NASA HPDE. While the Konis felt amazing in the first 15 minutes of a track day session, they felt noticeably softer and less responsive after 30 minutes of hard running. Meanwhile, the entry-level Teins felt exactly the same through the entire length of a 60 minute session at the same track.

While this consistency is a nice-to-have for most track day goers, it's actually a big deal for wheel to wheel racers. Club races tend to be rather close and it's normal to see battles for position right up to the checkered flag. Having a sharp and responsive car at the end of a race could make the difference between standing on the podium and fading into the midfield in the last few laps.

The other benefit to this approach is that the this makes the dampers incredibly tough. In the early days of my driving career I had a tendency of enjoying one or two off-track excursions during each track weekend. Those of you who have had a bad off know that the grassy areas in the infield of racetracks are deceptively bumpy and can wreak havoc on the undercarriage of your car. Yet in all of my off-roading adventures, I've never managed to bend or blow out a Tein suspension damper. While I no longer have a penchant for wild off-road antics, I still take advantage of their durability by attacking kerbing more aggressively than I used to. It's reassuring to know that I can bounce off of kerbs and occasionally take some liberties with track limits without worrying about damaging my suspension.

They Have Cool Features that are Actually Useful

It turns out that it's surprisingly difficult to develop meaningful new features for suspension dampers. Case in point, the most popular products in the Bilstein and Koni catalog haven't changed in decades. That hasn't stopped Tein from trying out quirky new things with their products. While many of their innovations are geared towards street use, some of them are actually useful for club racers.

My personal favorite is something Tein calls the Micro Speed Valve. It is one of the most clever innovations I have ever seen in a mass-market adjustable suspension damper.

In order to understand what the MSV does, you need to know a little bit about how adjustable dampers work. Almost all of the sub-$3000 coilover kits on the market today use a needle valve in a bypass hole to provide adjustable damping. And for good reason - Needle valve adjusters are simple, precise, durable, and cheap to make. Tein, Koni, Bilstein, Penske, Feal, Fortune Auto, and all of the cheaper Chinese and Taiwanese-built brands use this type of adjuster.

Cutaway diagram of the main piston of a suspension damper with a needle valve adjuster. Turning the knob at the top causes the needle valve in the middle to move up and down, adjusting the amount of fluid that flows through the bypass hole. Much of the shocks' damping force comes from the yellow valve shims, so by opening the valve and letting more fluid into the bypass hole, you can soften the damping. *Base diagram borrowed from the Tein USA blog. Sorry guys. Please don't sue.

An example of a needle out of a needle valve. Your adjustable dampers contain a tiny version of this that is only a few milimeters wide.

There's just one downside to this design. As you turn the adjusters towards full soft, more and more of the fluid flows through this bypass hole instead of going through the shim valves in the piston. In some situations, there will be so little fluid going through the piston that the dampers won't be able to do their job.

This isn't all that noticeable when you are driving over a kerb or driving over a rut because big impacts like these cause a lot of fluid to get pushed around within the shock. But in some cases, like through the turn-in phase of a high-speed corner, the forces could be so small that all of the fluid could end up going through the bypass hole instead of the piston. From the driver's seat, this translates to vague steering through high-speed corners and a weird floaty feeling through fast S-curves. This is about the last thing you want when you're pounding around a racetrack.

Cutaway diagram showing the MSV in action. Those tiny vertical yellow shims are the MSV. In real life they are tiny - mere millimeters across. *Again, diagram shamelessly copied from the Tein USA blog. Sorry guys. Please don't sue.

Tein's solution to this problem was to install a tiny set of shim valves on the bypass hole for the adjuster (and call it a Micro Speed Valve). These tiny shims provide a small amount of resistance when fluid goes through the bypass, which means that the dampers will provide consistent damping force even when the adjuster is set to full soft. It's a deceptively simple solution and it works remarkably well. A few years ago I instructed a novice driver who had MSV-equipped Tein Mono Flexes on his Acura. His car had fantastically responsive steering through high-speed corners despite the fact that he had the adjusters turned within a click or two of full soft. The car felt so good on Pocono's bumpy surface that we ended up leaving them that way.

Why is this useful for racers? The answer is Rain. Club racers tend not to touch their suspension once it's set. Unless it starts raining, in which case they all start scrambling to turn their dampers towards full soft. Although very few experienced club racers actually turn their dampers down that much, because they know that turning down the adjuster leads to vague steering. With MSV-equipped dampers, racers could soften their suspension without affecting the steering feel, potentially giving them an edge on a wet track.

Tein has also started using a Hydraulic Bump Stop (HBS) in some of their newer suspension kits. Basically, this is a valve built into the bottom of the shock that aggressively ramps up its damping as the shock reaches the limits of its travel. This prevents the car from bouncing uncontrollably when the suspension bottoms out over a big bump or a big rut.

While I have yet to sample one of Tein's HBS-equipped dampers on the track, I have ridden in an HBS-equipped street car and can attest that it soaks up speed bumps and potholes very nicely. I can see this being very useful in keeping a racecar settled over the alligator-strip type rumble strips that are so common on racetracks across North America.

The driver of ProjectCRX carefully avoiding the alligator strip (red arrow) through turn 10 at Summit Point. If the car's dampers had hydraulic bump stops, he would be able to drive right over that rough rumble strip

Very Responsive Local Service Center

One of Tein's selling points is that they have local service centers in all of their major markets. I never thought much of this, until the DMS suspension on our CRX developed a leak and needed to be sent away for a rebuild. My teammates and I still remember that nightmare of an experience. DMS's North American service center was so slow and unresponsive that it took three whole months to get two front dampers rebuilt. And that only happened after two of us had started calling them twice a week in an effort to hurry them along. I dread to think how long it would have taken if we didn't nag them as much as we did.

By comparison, Tein completed my last rebuild request in under two weeks, including the time it took to ship the dampers back from California to the east coast. They always picked up the phone when I called them and were happy to let me talk directly to the service techs so I could get my suspension set up exactly the way I wanted. When I asked a particularly tough question, they offered to make a call to Tein Japan to get me an answer. And to make the experience all that much sweeter, they charged us less than half of DMS's invoice for the same type of work.

This is a big deal for racers, who inevitably end up experimenting with spring rates and valving. Even the most expensive suspension dampers in the world won't do you any good if they're sitting in the shop for half of the season. Having previously purchased rebuild services from Tein USA, Koni NA, Bilstein, and DMS NA, I would say Tein's support services are by far the easiest to work with.

What are the downsides?

There are some drawbacks that come with all of these benefits.

The first is weight. The beefy construction of Tein's steel body dampers makes them heavier than other aftermarket dampers. This is especially noticeable on their MacPherson strut dampers, since they double-layer the steel on the lower brackets for extra rigidity. The larger diameter bodies also necessitate the use of larger diameter springs. For example, the Tein SS kit for the Prelude requires the use of 70mm ID suspension springs, which are not only heavier but are more difficult to find than the more common 60mm or 65mm sizes. While this only amounts to a weight penalty of 1-3 lbs per corner, those with cars that struggle to make minimum competition weight might balk at this.

Aside from Tein themselves, only Swift and Hyperco make the 70mm coilover springs that work with our extra-girthy dampers.

The second is that there is an extra fee if you order your Tein coilovers with custom valving. For example, if you want to order a set of Tein coilovers with custom spring rates, Tein will charge you anywhere up to $100 per corner. This is due to the fact that Tein centralizes the manufacturing, assembly, and packaging of its dampers in its factories in Japan. So unless your coilovers are a special order part, they can't customize the kit during assembly. In order to change the springing and valving on one of Tein's (rebuildable) coilover kits, their service techs needs to unbox a fully assembled set of coilovers and go through the same procedures as they would if they were rebuilding a set of used coilovers.

My solution for the latter problem is to buy a set of lightly used coilovers and to get them revalved before I put them on the car. Sure the dampers are a little dirty and the paint tends to be scratched up from use. But for the cost of a set of new coilovers I was able to get a set of used Tein Super Streets with track-focused valving and have enough money left over for a set of shiny new Swift coilover springs to go with them.

If you live in North America, another option is to get one of the sealed-body "Z" series coilovers. The non-rebuildable "Z" series dampers are made in a different factory in China, and can be custom-valved during assembly. I have no personal experience with this option, but seeing how Tein advertises this as one of the benefits of their new sealed dampers, I suspect this is also a cost-effective alternative.

Wait... doesn't Tein make actual racing dampers?

At this point you may be wondering why I've been focusing so much on Tein's street-able dampers when they have a line of actual competition dampers. After all, Tein has their Super Racing, Super Drift, and N1 dampers for road course use. Compared to their mainstream offerigs, all three of them are lighter, have more adjustability, and have track-specific valving right out of the box.

Price is the big obvious factor. A new set of Tein Super Racing coilovers costs twice as much as the next most expensive coilover kit in Tein's lineup. The top-of-the-line N1s are a special order part that comes in at between $750 - $1000 per damper. If you add a set of good springs and top hats, you are looking at a cost of $5000 - $6000 for a full kit. While this is actually still on the affordable side for a set of full-bore racing suspension, there are some very strong, established competitors in this price range (e.g. kits based on double adjustable Penske 7500s). This also happens to be quite a bit more than what most club racers are willing to spend on dampers and springs.

This exact setup can be yours for the eye-watering price of $5500. Which relatively speaking, isn't that bad. It's comparable to what companies like Penske, JRZ, AST, and KW will charge you for a product in the same performance group. For a budget oriented club racer though, it's a bit much.

The other reason is that Tein's street car dampers are, at their core, very decent high performance dampers. They are manufactured to extremely tight tolerances, are highly consistent from batch to batch, and the internal valving is configurable enough that they can be revalved to work with astronomically high spring rates. This is partly because Tein's mid-range products have the same exact core design their high-end competition dampers. For example, the older Super Street and Flex dampers share the same internal design with the competition-only Super Drift dampers, while the MonoFlex shares its internals with the highly rated Super Racing damper. And yes, this holds true for Tein's current product lineup as well. The Japan-market Racing Flex uses the same internal hardware as their budget-friendly Flex A, while their soon to be released Mono Racing is a more aggressively valved version of the affordable Mono Sport.

So why DO you keep buying Tein coilovers?

What it all comes down to is that Tein's products do everything that your average club racer or track day enthusiast needs. Their products are tough, consistent, have some unique features that are useful at the track, and come with excellent support at a very affordable price.

The kits are priced competitive enough that you can put together a custom suspension setup using on Tein coilovers on a budget of $1000 - $2500, including revalving fees. Case in point, I built the Prelude's suspension for just $1600, including the cost to upgrade to Swift 70mm main and helper springs.

With regular maintenance and the occasional rebuild, this setup has given us solid performance the better part of a decade. And as long as Tein's North American service center continues to provide the same outstanding support, there's a good chance that StudioVRM racecars will continue to run their tough green dampers for years to come.

See you at the track.

Disclosure Section:

Neither StudioVRM nor Roger Maeda are sponsored or supported directly by Tein USA or any of its subsidiaries. The USTCC series that we participate in is in fact sponsored by KW Suspension - which makes things a bit awkward since I'm effectively writing a positive review about a direct competitor of our sponsor.

If anyone from KW is reading this, well... sorry. But on balance, Tein has you beat at the moment.